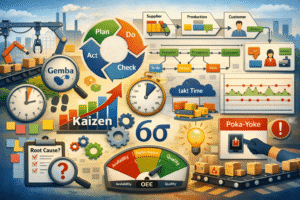

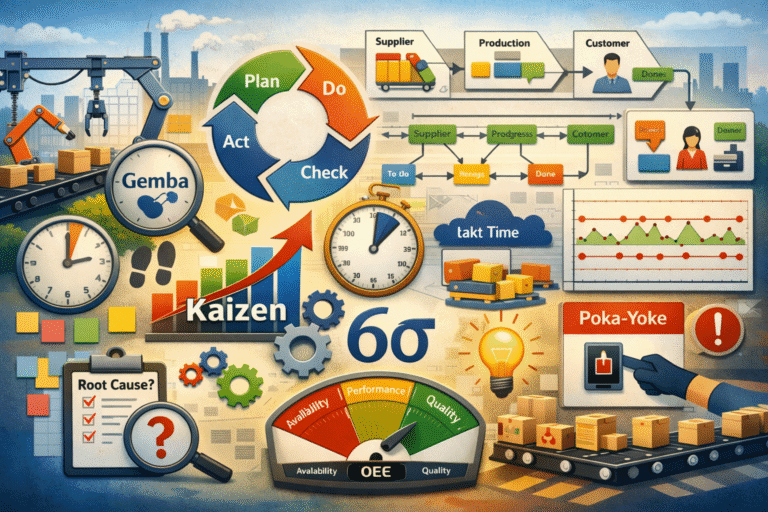

Having studied and lived operations management, I’ve compiled a cheat sheet of important philosophies and procedures anyone can implement at their company, applicable to building products in a factory, managing services like a digital marketing agency, and everything in between.

I can’t stress this enough: Implementing even one of these strategies will improve your workplace.

Control Charts:

- p-charts track defective units (yes/no per unit).

- c-charts track number of defects per unit.

Documented Standard Work:

- Defines what steps are performed, in what sequence, by whom, in how much time, using what materials or tools, to what quality standard.

- Core concept: You can’t improve a process reliably if it changes every time someone performs it.

Flow and Stream Maps:

- Process flow map: A visual diagram showing the sequence of steps in a process from start to finish, identifying what happens first, next, and last.

- Value stream map: A visual diagram that shows every step required to deliver a product or service, from initial request to the final customer.

- Core differentiation: A process flow map shows what happens while a value stream map shows how efficiently it happens.

Gemba (Go See):

- Managers need to occasionally get onto the front line and actually see what’s happening and actually interact with customers.

Heijunka (Production Leveling):

- Balancing a work schedule so it is consistent throughout each process.

- Core concept: Customer demand can be irregular, making for irregular production that can burnout workers and equipment. Heijunka smooths this out.

- Example: Customer demand is x amount of this product or service, y amount of this, and z amount of that. Instead of building or doing all of x then all of y then all of z, you spread them out in a pattern.

Jidoka (Stop to Fix):

- Motivation that stops machines or processes when they identify a defect.

- Core concept: Don’t pass an error onto the next person in the process!

Just-in-Time and Continuous Flow inventory philosophies:

- JIT: Materials, components, and products are produced or delivered only when needed, in the amount needed, at the needed time (no keeping excess inventory).

- Continuous Flow (One-Piece Flow): Move products through the production process one unit at a time, without waiting, batching, or stopping (instead of producing in large batches and moving them between departments).

Kaizen (Continuous Improvement):

- Everyone always working to get just a little better each time, every day. A collective process for gradual but important improvement.

Kanban:

- A visual “pull” system that signals when and how much to produce, preventing overproduction and excess inventory

- Core concept: Take only exactly what is needed.

- Example: Chipotle making a burrito for you in the moment, versus McDonald’s stacking inventory of burgers.

OEE (Overall Equipment Effectiveness):

- Measure effectiveness by looking at availability, performance, and quality

PDCA (Plan, Do, Check, Act):

- A four-step method for continuous process improvement where you plan (identify a problem or opportunity), do (implement a change as a pilot test), check (evaluate the results), and act (either implement the change or don’t based on the results).

Poka-yoke:

- Implementing practices that look to prevent human error.

- Example: If a diesel gas novel is larger than a “standard” gas nozzle so someone can’t accidentally incorrectly fill their car with diesel gas.

- Fun anecdote: This is one of my favorites! Just try saying it: POH-kay YOH-key!).

Process Capability Index:

- A statistical measurement identifying how well a process can produce results within defined specification limits (is this process capable of consistently meeting requirements?).

- Core concept: Computing process capability.

Root Cause Analysis:

- Using problem-solving to find the root cause of an issue to truly prevent reoccurrence.

SIPOC (Suppliers, Inputs, Processes, Outputs, Customers):

- A structured way to summarize a process at a high level before diving into detailed analysis.

- Core concept: Who is involved, what goes in, what happens, what comes out, who receives it?

Six Sigma:

- A data-driven methodology for reducing defects and variations in processes to improve quality and performance.

- Core concept: Reduce defects in products or processes.

- Core core concepts: Reduce defects to 3.4 defects per million opportunities (DPMO).

- Core goal: Reduce variation so outputs consistently meet customer specifications.

- Main method: DMAIC (Define, Measure, Analyze, Improve, Control).

- Fun anecdote: I’ve considered getting a tattoo of “6σ” to always remind myself to be Kaizening to minimize defects (yes, I crossed philosophies there).

SMART Goals (Specific, Measurable, Attainable, Relevant, Time-specific):

- More than just KPIs, they are smart goals!

SPC (Statistical Process Control):

- Instead of reacting to failure, you should manage quality in real time, typically via the use of a control chart (see the very first bullet in this list).

Takt Time:

- The pace of production.

Throughput Analysis:

- The study of how much output a process or system can produce over a given period of time…and what is limiting it.

- Throughput: The rate of flow through a system.

- Cycle time: The time it takes to complete one unit of output from start to finish.how

- Core concept: Used to eliminate bottlenecks and constraints.

- Consider: Value added time and non-value added (particularly within cycle time)

5S (Sort, Set in order, Shine, Standardize, Sustain):

- A workplace organization method designed to improve efficiency, safety, and flow by creating a clean, organized, and standardized work environment.

- Core concept: Take a workspace with scattered tools that cause wasted time searching and instead create labeled tool stations or pre-packaged components.

Want any help implementing efficiencies to streamline your processes, make your employees happier, and improve profitability? Good thing Arc Intermedia does consulting!

You’re also welcome to contact us anytime to talk through issues or possible improvements.